당신은 주제를 찾고 있습니까 “5 8 square broach – Spare Parts #13 – Making A Square Broach“? 다음 카테고리의 웹사이트 https://ppa.pilgrimjournalist.com 에서 귀하의 모든 질문에 답변해 드립니다: ppa.pilgrimjournalist.com/blog. 바로 아래에서 답을 찾을 수 있습니다. 작성자 Clickspring 이(가) 작성한 기사에는 조회수 2,147,184회 및 좋아요 33,989개 개의 좋아요가 있습니다.

Table of Contents

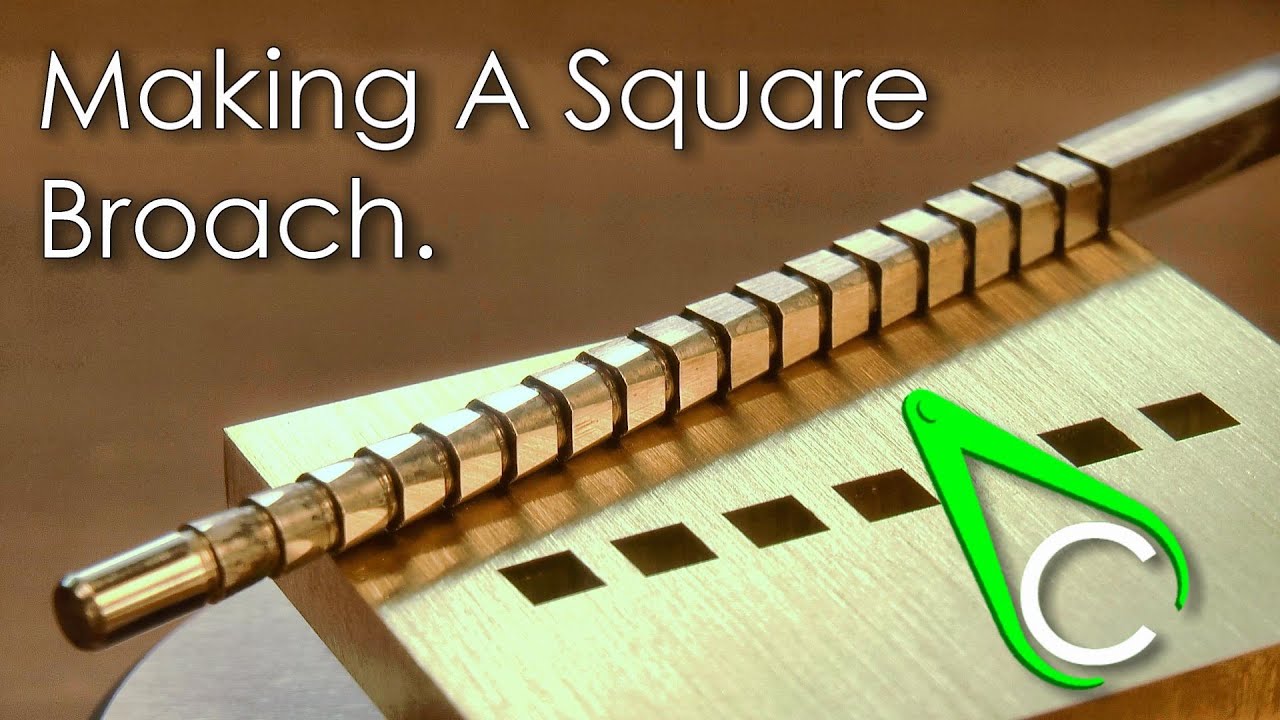

5 8 square broach 주제에 대한 동영상 보기

여기에서 이 주제에 대한 비디오를 시청하십시오. 주의 깊게 살펴보고 읽고 있는 내용에 대한 피드백을 제공하세요!

d여기에서 Spare Parts #13 – Making A Square Broach – 5 8 square broach 주제에 대한 세부정보를 참조하세요

Making A Square Broach, by Clickspring.

It’s not necessarily a common event, but when you need to make a square hole, it can be difficult to get a precise result. One of the best methods to achieve a professional cut is to use a custom made broach, so in this video I go through the process of making one from scratch.

Free Plans: http://www.clickspringprojects.com/uploads/3/8/2/2/38221101/small_square_broach_brass_only.pdf

If you would like to help support the creation of these videos, then head on over to the Clickspring Patreon page: https://www.patreon.com/clickspring

________________________________________________________

A very special thank you to patron Dan Keen.

________________________________________________________

You can also help me make these videos by purchasing via the following Amazon Affiliate links:

Cameras used in this video:

Panasonic GH5 – https://amzn.to/2rEzhh2

Panasonic X920 – https://amzn.to/2wzxxdT

Tools \u0026 Shop Products:

\”Solidworks 2013 Bible\”: http://amzn.to/2FObS1D

\”Hardening, Tempering and Heat Treatment (Workshop Practice Series)\” – https://amzn.to/2KbZo6l

Sherline Lathe: http://amzn.to/2pnXM19

Sherline WW collets: http://amzn.to/2FYZ7F8

Heavy Duty Arbor Press: http://amzn.to/2G4gog7

Generic Dial Indicator 0.001\”: http://amzn.to/2FOFTyF

Norton 1-by-2-by-8-Inch Fine/Coarse India Combination Oilstone, Red: http://amzn.to/2tTEPb0

Kaowool 24\” X 12\” X 1\” 2400 F Ceramic Fiber Insulation: http://amzn.to/2pfsM3d

Abbreviated Transcript:

00:06 No matter what your style of metal working project might be, every now and then there’s a need to form a precise square hole.

00:21 A pilot hole locates the exact position of the desired square, and then the broach is forced through the workpiece.

00:53 And that’s because, all of the teeth prior to the last tooth collectively prepare the opening for the final tooth to set the dimension, so within reason, we can tolerate some small errors in those teeth, providing that the very last one is correct.

01:26 Its much too long and slender to be turned between centers, so I’ll need to form the features by incrementally extending the work from a 4 jaw chuck. And the other key feature is the pilot diameter, which must be centered on the square, so I’m taking care to center the raw stock prior to forming that cylindrical shape.

01:48 I have the work reasonably well centered to begin with, so that when I position the dial indicator, the error that I see for each jaw is quite small I then use 2 chuck keys in opposition to each other, to move the work, so that the dial reads directly between the original 2 readings for both jaws.

02:13 Once its close, I move the zero reference to that point, so that becomes my target when I start to center the other two jaws. Once the work gets close to being centered, the errors start to sit nicely either side of that zero reference, and it gets easier to pull it into position.

02:53 But even doing this quickly, you can see that it will take a fair amount of time to do this for every cut, so there’s a strong incentive to bypass this centering process if we can. For now though, the work is centered, so I can make a start on cutting that pilot diameter.

03:39 Next I’m using the first groove position to register the tool after extending the work, and then I’m using the hand wheels to advance the tool the required amount to form the next groove. Now inevitably I will have introduced a small eccentricity to each of these cuts, and the teeth won’t be precisely spaced either. But as I mentioned before, they don’t really need to be.

04:14 Providing I don’t introduce any gross errors, It’s close enough for the final result, and by accepting a small error, I can move through this part of the process very quickly.

05:14 The total amount of metal to be removed, is determined by the difference between the pilot diameter and the diameter of the circle that just encloses the final square. That metal removal must now be shared across all of the teeth, so it determines how much I feed out before cutting each tooth, and that in turn ends up determining the broach depth of cut.

05:32 The diameter difference also gives an indication of how many teeth are required to keep the chip load manageable.

06:15 At this point all of the features of the broach have been formed, so it can now be quench hardened, and on this occasion I’m using the tray that I recently made for the current clock project.

07:07 In an industrial setting a broach is far more likely to be pulled through the work rather than pushed like this, and there’s a real risk of fracture using an arbor press in this way, so be sure to take it carefully.

07:19 Make sure the broach is perfectly vertical before you push it through, and as always have your eye protection on. But even with all of the compromises, its still a great way to use home shop tools to quickly shape a precise square hole.

Making A Square Broach, by Clickspring.

5 8 square broach 주제에 대한 자세한 내용은 여기를 참조하세요.

5/8 in Square Size, 21/32 in Drill Size, 16 13/16 in Broach Lg …

Looking for Square Broach, Fractional Inch, 5/8″? … Square broaches create a square hole from an existing round pilot hole in a single pass.

Source: www.grainger.com

Date Published: 7/28/2021

View: 1539

5/8″ Square Keyway Broach – USA – eBay

Broach Length: 16-13/16″. Keyway Size: 5/8. NOTE: Standard square broaches are HSS push type designed for one-pass finishing when used with arbor or …

Source: www.ebay.com

Date Published: 9/28/2021

View: 2623

5/8″ Standard Square Broach, Bright Finish

5/8″ Standard Square Broach, Bright Finish. PILOT PRECISION PRODUCTS. 66615. 66615. 66615. 0.6250″ 5/8″. Brand: PILOT PRECISION PRODUCTS. $384.00. $364.80.

Source: www.suncoasttools.com

Date Published: 10/19/2021

View: 5536

Square Broaches – MSC Industrial Supply

5/16″ x 7-7/8″ Overall Length, 21/64″ Pilot Hole Diam, Square Broach0.313 to 0.314″ Tolerance, 0.437 to 0.439″ Across Corners, 7/32″ Pitch, 3/8 to 1″ LOC, …

Source: www.mscdirect.com

Date Published: 6/8/2021

View: 1484

주제와 관련된 이미지 5 8 square broach

주제와 관련된 더 많은 사진을 참조하십시오 Spare Parts #13 – Making A Square Broach. 댓글에서 더 많은 관련 이미지를 보거나 필요한 경우 더 많은 관련 기사를 볼 수 있습니다.

주제에 대한 기사 평가 5 8 square broach

- Author: Clickspring

- Views: 조회수 2,147,184회

- Likes: 좋아요 33,989개

- Date Published: 2016. 3. 27.

- Video Url link: https://www.youtube.com/watch?v=MYI1slVGziU

5/8″ Square Rotary Broach 1/2″ Shank Diameter

5/8″ Square Rotary Broach | 1/2″ Shank Diameter x 1-3/4″ Overall Length

Polygon’s standard 5/8″ square rotary broaches are made from high quality M-2 high speed steel and precision ground to tight tolerances for superior broaching performance. Ground shank diameters insure that Polygon’s 5/8″ square broaches fit all commercially available broach holders. Nominal sizes meet ASME standards for socket clearances and include pressure relief vent holes to reduce pressure and improve tool life. Standard broaching depths are 2x the across flat dimensions and provide maximum clearance. Custom options include premium broach materials, coatings, dimensions and tolerances.

*Note: This form is typically too large for some rotary broaching applications. Call us to discuss your project.

Part Number: S06305B

Square Broach: 5/8 in Square Size, 21/32 in Drill Size, 16 13/16 in Broach Lg, 5/8 in Min. Lg Of Cut

Square broaches create a square hole from an existing round pilot hole in a single pass. Sometimes called square hole broaches or square punch broaches, they are often used to punch square holes in fixtures, jigs, and sockets. Square broach tools are operated with a hand press or hydraulic arbor press in metalworking tasks.

View More

HASSAY SAVAGE 5/8″ Broach Size Square Broach

Benefits

Broach is tapered, allowing teeth to cut holes to proper depth and width.

Used to machine internal and external surfaces, such as holes, keyways, and teeth of internal gears.

Manufactured from high speed steel for longer tool life.

The high cost is justified because of their use for high-production runs.

Applications

For cutting square shaped holes in round pilot holes.

Designed to be used manually with an arbor press to produce the square holes.

Used to re-cut a round hole into a hole having a square shape in a single pass through the workpiece.

Design allows broach to start in a plain round hole and cut a precisely shaped square in a single pass through the hole.

Well suited for use in a variety of ferrous and non-ferrous materials.

Features

Hardened and ground bars with cutting teeth on their periphery.

Made to cut either inch or millimeter size square holes.

Sized and proportioned to afford a good cutting range and ample rigidity.

Each tooth is progressively larger and each cuts slightly deeper than the tooth before.

Full square broaches, which leave no radius in the flats of the broached piece, are also available (the pilot diameter will equal the finished square size).

Bright finish.

Technical Data

Manufactured from high speed steel.

Broach is tapered, allowing teeth to cut hole to proper depth and width.

Made to cut either inch or millimeter size square holes.

Bright finish.

Use Hassay Savage HSS Square Push Broaches for Successively Deeper Cuts. HSS Square Push-type Broach is tapered and ground with a bright finish. It is majorly used to cut square shaped holes in round pilot holes on both ferrous and non-ferrous materials. The product in focus is available in Size from 1/8 inch to 1 inch with Broach length ranging from 4-1/8 inches to 24-1/8 inches. The length of a broach tool is usually determined by the amount of stock to be removed, and limited by the machine stroke. Subsequently, the rear pilot maintains tool alignment as the final finish teeth pass through the workpiece hole and this product has a Pilot diameter ranging from 0.1285 inch to 1.0938 inch. The square broach can execute a Drill size extending up to a maximum of 1-3/32 inches. Whereas the minimum length of cut is 3/16 inch & the maximum length of cut is 2 inches and tolerance is said to be +0.0005 inch / -0.001 inch. Hassay Savage standard square broaches are made up of high speed steel. They are push type and therefore ideal for external broaching in which material is removed directly from the surface of a workpiece. They are designed for one-pass finishing when used with arbor or hydraulic press, or vertical broaching machine. Why Hassay Savage broaches are leading solutions in the market is because of its quality: The side relief eliminates drag in multiple-pass broaching. Tooth-relief, using Borazon wheels, improves surface finish and extends tool life. Precision grinding of the rake face ensures consistent performance and free cutting action after several sharpenings. Complete accuracy of ground chip breakers eliminates drifting. An undercut pilot allows easier entry on each pass. From the craftsmanship of Hassay Savage toolmakers to the tight standards of their quality control, you can always be assured of excellent performance from a Hassay Savage HSS broach. Broaching closely competes with other processes, such as boring, milling, shaping, and reaming. However expensive the broaching process be, the overall cost tends to justify their use for high-production runs.

Broach Standard Square 1/8 5/32 3/16 1/4 9/32 5/16 11/32 3/8 13/32 7/16 15/32 1/2 9/16 5/8 11/16 3/4 7/8 1 Inch Sizes ID 1173-

Broach Standard Square 1/8 5/32 3/16 1/4 9/32 5/16 11/32 3/8 13/32 7/16 15/32 1/2 9/16 5/8 11/16 3/4 7/8 1 Inch Sizes ID 1173-Standard Square Broaches are designed to generate in one-pass a Standard Square hole in a previously cast or drilled round hole.Standard Square Broaches begin in an oversized pilot hole and generate the square hole while leaving small radii on the flats.Available from stock in the most common American Standard sizes (1/8″-1″).Specials: We are fully equipped to manufacture Special Standard and Full Square Broaches to your specifications.All standard items are available with TiN, or TiAlN coatings. Please contact us for details

5/8″ Square Keyway Broach – USA

Estimated delivery dates – opens in a new window or tab

include seller’s handling time, origin ZIP Code, destination ZIP Code and time of acceptance and will depend on shipping service selected and receipt of

cleared payment cleared payment – opens in a new window or tab

. Delivery times may vary, especially during peak periods.

Hassay Savage HSS Inch Square Push Broach, 5/8″ Size – 13040 – 30-666-615

Hassay Savage HSS Inch Square Push Broach, 5/8″ Size – 13040 – 30-666-615

Broach is tapered, allowing teeth to cut holes to proper depth and width.

Used to machine internal and external surfaces, such as holes, keyways, and teeth of internal gears.

Manufactured from high speed steel for longer tool life.

The high cost is justified because of their use for high-production runs.

For cutting square shaped holes in round pilot holes.

Designed to be used manually with an arbor press to produce the square holes.

Used to re-cut a round hole into a hole having a square shape in a single pass through the workpiece.

Design allows broach to start in a plain round hole and cut a precisely shaped square in a single pass through the hole.

Well suited for use in a variety of ferrous and non-ferrous materials.

Hardened and ground bars with cutting teeth on their periphery.

Made to cut either inch or millimeter size square holes.

Sized and proportioned to afford a good cutting range and ample rigidity.

Each tooth is progressively larger and each cuts slightly deeper than the tooth before.

Full square broaches, which leave no radius in the flats of the broached piece, are also available (the pilot diameter will equal the finished square size).

Bright finish.

Manufactured from high speed steel.

Broach is tapered, allowing teeth to cut hole to proper depth and width.

Made to cut either inch or millimeter size square holes.

Hardness: 58 to 60 RC

Bright finish.

5/8″ Standard Square Broach, Bright Finish

5/8″ Standard Square Broach, Bright Finish Pilot Precision Products – Dumont Minute Man® Standard Square Broaches Are Designed To Generate In One Pass A Standard Square Hole In A Previously Cast Or Drilled Round Hole. Standard Square Broaches Begin In An Oversized Pilot Hole And Generate The Square Hole While Leaving Small Radii On The Flats. Dumont Part #66615

Additional Product Details

키워드에 대한 정보 5 8 square broach

다음은 Bing에서 5 8 square broach 주제에 대한 검색 결과입니다. 필요한 경우 더 읽을 수 있습니다.

이 기사는 인터넷의 다양한 출처에서 편집되었습니다. 이 기사가 유용했기를 바랍니다. 이 기사가 유용하다고 생각되면 공유하십시오. 매우 감사합니다!

사람들이 주제에 대해 자주 검색하는 키워드 Spare Parts #13 – Making A Square Broach

- broach

- broaching a hole

- square hole

- make a square hole

- making

- maker project

- clockmaking

- machine shop

- model engineering

- Home Machining

- machine shop projects

- Machining

- Metal

- hand tools

- clock maker

- home shop project

- clickspring

Spare #Parts ##13 #- #Making #A #Square #Broach

YouTube에서 5 8 square broach 주제의 다른 동영상 보기

주제에 대한 기사를 시청해 주셔서 감사합니다 Spare Parts #13 – Making A Square Broach | 5 8 square broach, 이 기사가 유용하다고 생각되면 공유하십시오, 매우 감사합니다.